Many product developers struggle to find a material that provides high structural integrity without sacrificing breathability. When garments or industrial components trap heat and moisture, the resulting discomfort can significantly degrade the quality of the final user experience. Selecting a high-performance mesh type fabric offers the perfect solution for achieving superior ventilation and moisture-wicking across fashion and technical sectors.

What defines a mesh type fabric?

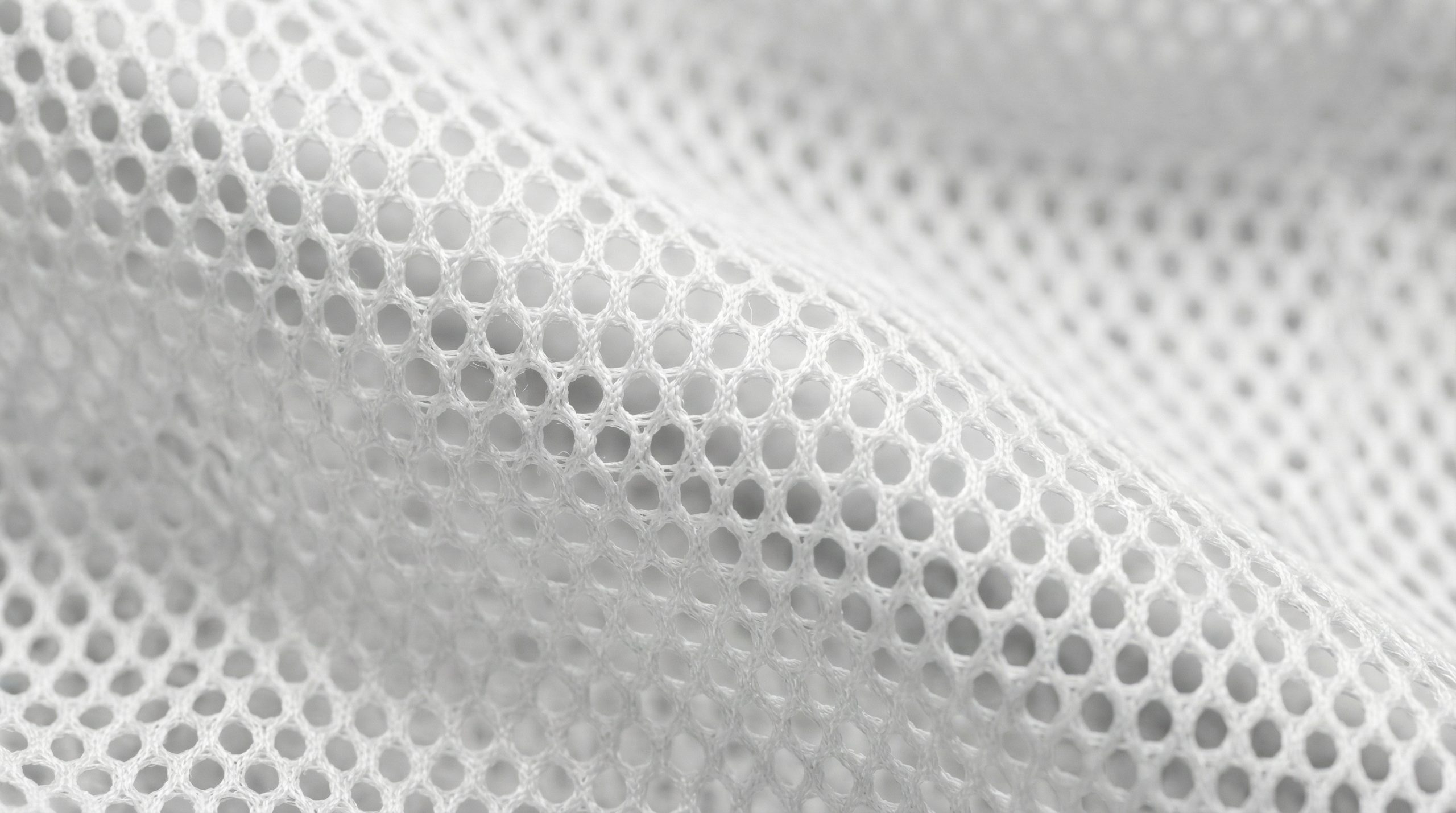

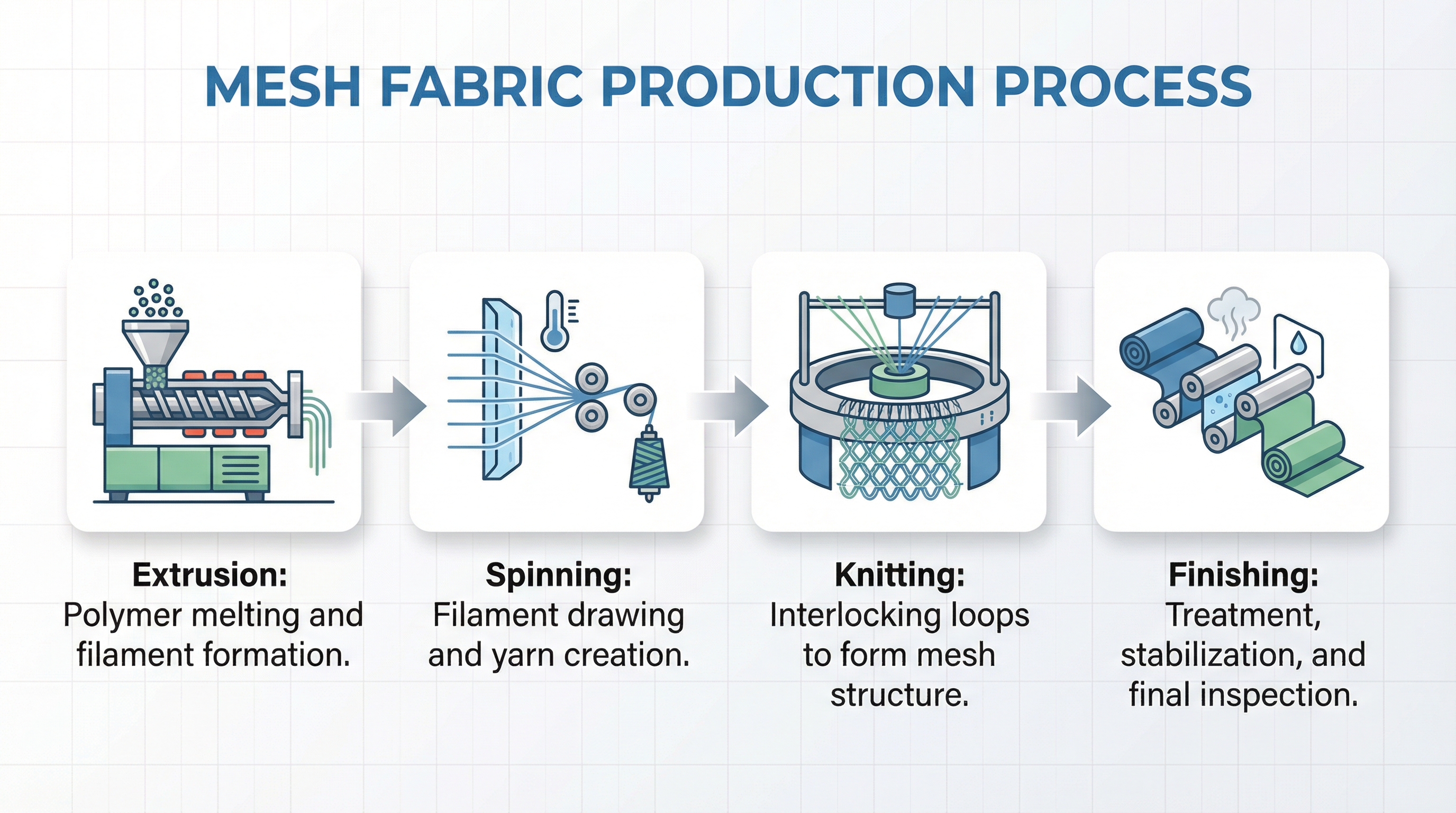

Mesh is a textile characterized by its open-weave, net-like structure which creates thousands of tiny holes for maximum airflow. Most modern varieties are constructed from synthetic fibers like polyester or nylon to ensure the material remains lightweight yet durable.

The fundamental weave structure

Think about it:

- Yarns are spaced out to create a permeable surface.

- The “Holes Per Inch” (HPI) typically ranges from 6 to 16.

- Strategic spacing allows for high visibility and air passage.

Common fiber compositions

Here is the deal:

- Polyester is favored for its moisture-wicking and athletic performance.

- Nylon is often selected for its superior strength and abrasion resistance.

- Silk mesh remains a luxury option for high-end couturiers.

| Feature | Specification | |

|---|---|---|

| Structure | Net-like / Open-weave | |

| HPI Range | 6 – 16 Holes | |

| Key Property | Maximum Breathability | |

| Primary Use | Ventilation |

Key Takeaway: Mesh is defined by its permeability and “holed” appearance, making it the industry standard for ventilation.

How is mesh type fabric produced?

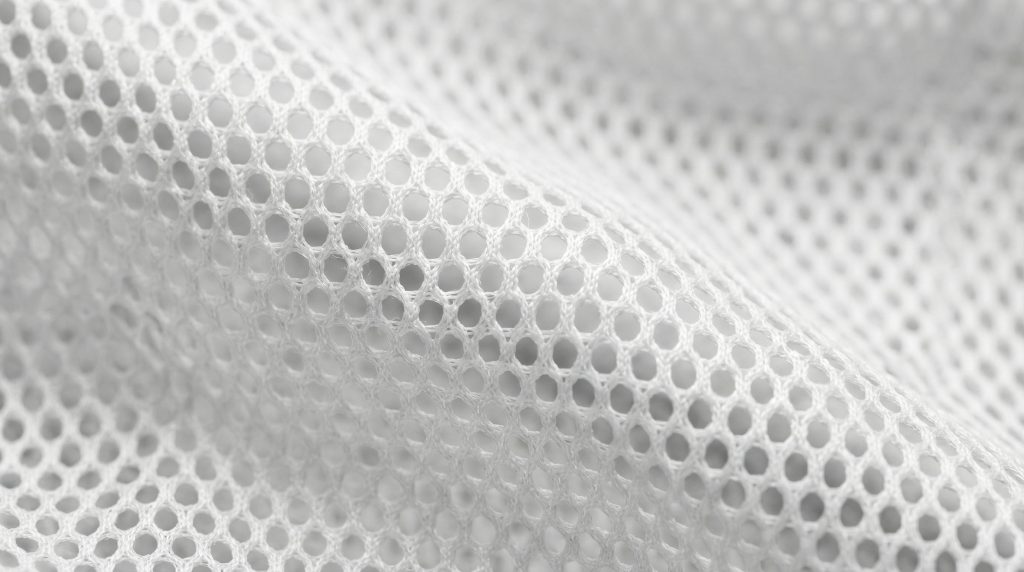

The production begins with the extrusion of petroleum-based polymers into fine synthetic strands. These strands are then spun into yarns and processed through specialized knitting or weaving machines to form the characteristic open pattern.

Extrusion and spinning phases

The best part?

- Polymers are melted and forced through spinnerets to create uniform strands.

- These strands are cooled and wound onto spools for textile processing.

- Consistent extrusion ensures the final fabric maintains its mechanical properties.

Knitting and finishing steps

Look no further:

- Precision looms interlock loops to create consistent hexagonal or square holes.

- Heat-setting processes stabilize the fabric to prevent future shrinking.

- Chemical finishes can be applied to enhance fire resistance or UV stability.

| Stage | Industrial Process | |

|---|---|---|

| Extrusion | Melting polymers into filament strands | |

| Spinning | Forming yarn spools from filaments | |

| Knitting | Creating the open-hole net pattern | |

| Finishing | Stabilizing and treating the textile |

Key Takeaway: The production process relies on precision machinery to ensure the “holes” remain uniform and structural.

Is mesh type fabric used in dresses?

Designers frequently utilize variants like tulle for bridal wear and evening gowns to add volume without excessive weight. When creating ethereal silhouettes, many manufacturers rely on specialized bridal dress tulle to achieve a floaty, semi-transparent aesthetic.

Aesthetic and structural benefits

You might be wondering:

- Mesh provides the necessary rigidity for structured skirt layers.

- It allows for illusion necklines that appear invisible against the skin.

- The material is easily layered to create complex, multidimensional textures.

Specialized tulle applications

Believe it or not:

- Tulle is often bunched to create ruffles and traditional tutus.

- It serves as a base for intricate embroidery and sequin work.

- Modern formalwear uses it to provide support in corset-style bodices.

| Application | Benefit | |

|---|---|---|

| Bridal Veils | Lightweight transparency | |

| Skirt Overlays | Structural volume | |

| Illusion Panels | Seamless skin-tone matching |

Key Takeaway: Delicate mesh variants provide the necessary volume and “floaty” texture essential for the bridal and formalwear industries.

Why buy a specific mesh type fabric?

Different industrial applications require specific levels of stretch, weight, and hole density to ensure the fabric performs under stress. For heavy-duty gear, sourcing a high-density bag & luggage mesh ensures that products withstand abrasive environments without tearing.

Performance metrics for selection

Keep this in mind:

- Moisture-wicking is vital for athletic and activewear sectors.

- Tensile strength determines the fabric’s suitability for load-bearing bags.

- Air permeability dictates the comfort level in high-heat industrial settings.

Application-driven utility

The secret is:

- Footwear mesh must offer abrasion resistance and multidirectional support.

- Industrial netting requires chemical resistance and high UV stability.

- Shapewear relies on specific compression ratios for body contouring.

| Selection Factor | Industrial Benefit | |

|---|---|---|

| Tear Strength | Longevity in luggage and gear | |

| Breathability | Enhanced comfort for activewear | |

| Elasticity | Precision fit in footwear and support |

Key Takeaway: Selecting a task-specific mesh ensures the material meets the mechanical demands of the intended environment.

Where is mesh type fabric produced?

While the concept of mesh originated in the United Kingdom, global production is now concentrated in high-output Asian manufacturing hubs. China remains the leading exporter, leveraging advanced synthetic fiber infrastructure to supply the majority of the world’s commercial mesh.

Global manufacturing centers

Here is the deal:

- China produces the highest volume of polyester and nylon mesh.

- India and Indonesia are growing suppliers for the garment industry.

- The UK and USA specialize in high-tech, military-grade technical mesh.

Export standards and logistics

Don’t forget:

- ISO 9001 certifications are standard for major international suppliers.

- Global shipping networks facilitate rapid sourcing for large-scale brands.

- Regional specialties determine where technical or fashion mesh is sourced.

| Region | Production Specialty | |

|---|---|---|

| China | High-volume synthetic mesh | |

| United Kingdom | Heritage and technical weaves | |

| United States | Military and aerospace standards |

Key Takeaway: China remains the preeminent supplier of mesh due to its advanced synthetic fiber infrastructure and production scale.

What is a polyester mesh type fabric?

Polyester is the most common variety of mesh type fabric, favored for its durability and resistance to stretching or shrinking. This synthetic material is specifically engineered for moisture-wicking, making it the primary choice for professional sports jerseys and athletic equipment.

Advantages in sportswear

The fact is:

- It does not absorb moisture, keeping the athlete light during exercise.

- The fabric is highly resistant to pilling and general wear.

- It maintains vibrant colors even after repeated high-temperature washing.

Industrial and filter utility

Watch this:

- Polyester mesh is used in screen printing due to its stability.

- Its chemical resistance makes it suitable for industrial filtration.

- Low heat retention ensures it remains comfortable in hot environments.

| Property | Rating | |

|---|---|---|

| Durability | Very High | |

| Moisture Wicking | Excellent | |

| Color Retention | High |

Key Takeaway: Polyester is the preferred material for athletic applications because it does not absorb sweat, keeping the wearer light.

Does mesh type fabric offer stretch?

Standard mesh offers minimal mechanical stretch, but adding elastane or spandex creates a highly elastic variant. Specialized power mesh provides four-way stretch and excellent recovery, making it essential for the compression and shapewear markets.

Understanding 4-way stretch

Check it out:

- Spandex blends allow the fabric to expand and contract instantly.

- Recovery properties ensure the garment maintains its original shape.

- It is frequently used in the panels of high-performance footwear.

Compression and support

The bottom line:

- High-stretch mesh provides medical-grade support in orthopedic braces.

- It offers smoothing and contouring effects in lingerie and hosiery.

- Athletes rely on it for muscle stabilization during high-impact activities.

| Stretch Type | Composition | |

|---|---|---|

| Two-Way | Polyester / Nylon Base | |

| Four-Way | Polyester-Spandex Blend | |

| Mechanical | Knit Pattern Influence |

Key Takeaway: The degree of stretch is determined by the inclusion of elastic fibers and the specific knitting technique used.

How to price a mesh type fabric?

Pricing for mesh is determined by the raw fiber cost, the complexity of the knitting pattern, and the dyeing process. While standard polyester mesh is highly affordable, technical variants with specific certifications often command a premium price in the B2B market.

Factors influencing cost

Think about it:

- Silk-based mesh is significantly more expensive than synthetic options.

- Hexagonal tulle patterns require more complex machinery than square weaves.

- Custom dyeing or antimicrobial treatments add to the final yardage price.

Wholesale vs. technical pricing

Here is the deal:

- Bulk orders from high-output factories reduce the cost per yard.

- Certified flame-retardant or UV-stable meshes are priced for performance.

- Sourcing from domestic warehouses may increase price but reduce lead times.

| Cost Factor | Impact | |

|---|---|---|

| Material | Silk (High) / Polyester (Low) | |

| Volume | Wholesale discounts apply | |

| Treatment | Custom coatings increase cost |

Key Takeaway: While synthetic mesh is generally affordable, technical and high-fashion variants can command a premium price.

Is mesh type fabric safe for cars?

Automotive-grade mesh is specifically engineered to meet strict safety standards, including flame retardancy and UV resistance. Utilizing a certified automotive interior mesh ensures that vehicle seats and headliners remain durable under constant sunlight and abrasion.

Regulatory and safety standards

Look no further:

- Fabrics must meet FMVSS 302 standards for fire resistance.

- High Martindale test scores are required for seat durability.

- UV stability prevents the mesh from becoming brittle in the sun.

Interior comfort and design

The best part?

- Breathable mesh seats improve passenger comfort during long drives.

- It offers a modern, tech-focused aesthetic for contemporary cabins.

- Lightweight mesh helps reduce the overall weight of the vehicle.

| Standard | Safety Requirement | |

|---|---|---|

| Fire Resistance | FMVSS 302 Compliance | |

| Abrasion | High Martindale Rating | |

| UV Stability | Sunlight fade resistance |

Key Takeaway: Mesh used in vehicles must pass rigorous safety and environmental tests that standard apparel mesh does not.

How to care for mesh type fabric?

Most mesh products require gentle care to prevent the delicate open-weave structure from snagging or tearing. Proper maintenance ensures that high-performance items, such as footwear mesh , maintain their structural integrity and breathability over time.

Washing and drying protocols

Here is the deal:

- Use cold water and a gentle cycle to protect the fibers.

- Always air dry to prevent heat damage from industrial dryers.

- Use a protective laundry bag to avoid snags from zippers or hooks.

Stain removal and repair

The secret is:

- Blot stains immediately rather than rubbing to avoid fiber distortion.

- Use mild detergents to preserve the elasticity of power mesh.

- Small tears can be repaired with clear thread to prevent unraveling.

| Care Step | Recommendation | |

|---|---|---|

| Water Temp | Cold / Lukewarm | |

| Drying Method | Air Dry Only | |

| Protection | Use Laundry Bag |

Key Takeaway: Proper maintenance involving low heat and protective wash bags will significantly extend the lifespan of mesh garments.

FAQ

Can I wash mesh garments in a machine? Yes, but you should always use a delicate cycle and place the item inside a protective laundry bag to prevent the open weave from snagging on other clothes.

What’s the best mesh type fabric for summer wear? Polyester mesh is generally the best for summer because it is exceptionally breathable and features moisture-wicking properties that help keep your skin dry.

Can I use mesh for industrial filters? Absolutely. Many high-density nylon meshes are used in industrial filtration and screen printing due to their uniform hole size and chemical resistance.

What’s the best way to sew this fabric? When sewing mesh, it is best to use a ballpoint needle and a zigzag stitch to allow the fabric to stretch without snapping the threads.

Can I recycle synthetic mesh materials? While traditional polyester is difficult to biodegrade, many manufacturers now offer mesh made from 100% recycled PET plastics, which can be certified by the Global Recycle Standard.

Conclusion

Mesh fabric is an indispensable material in modern textiles, offering a unique combination of breathability, elasticity, and strength. Whether you are developing high-performance athletic gear, luxury bridal gowns, or durable automotive interiors, understanding the nuances of the weave and fiber choice is critical. By selecting the appropriate variant, you ensure both the functionality and longevity of your product.

Ready to find the perfect textile for your next project? contact us today for expert guidance on selecting and sourcing the ideal mesh for your needs.