Real Results from Real Partnerships

Discover how leading brands have transformed their product lines with our high-performance apparel mesh fabrics. From enhanced comfort to superior breathability and structural support—see the measurable impact our solutions deliver across diverse garment categories.

European Sportswear Brand

US Bridal Collection

Asian Lingerie Brand

Customer Needs Analysis

Every successful partnership begins with understanding your unique challenges. Discover how we identified and addressed the specific pain points that led our clients to choose Apparel Mesh as their fabric solution.

European Sportswear Brand

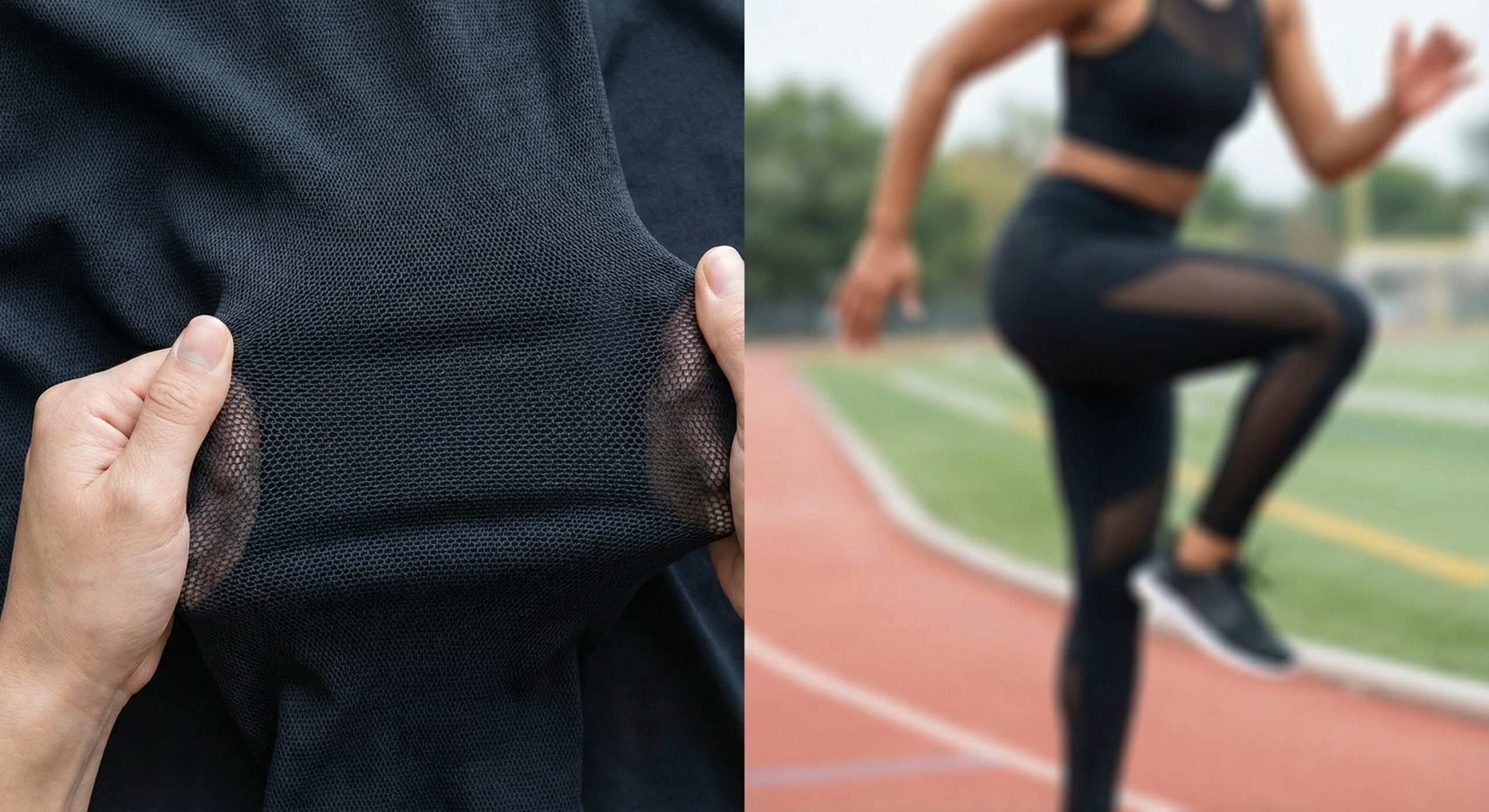

High-Performance Athletic Wear Production

A leading European activewear brand required mesh fabric that could deliver consistent stretch performance across large-scale production runs without compromising on compression support.

US Bridal Designer

Premium Wedding Dress Collection

A prestigious American bridal designer needed ultra-fine mesh with perfect transparency consistency and luxuriously soft hand-feel for their high-end wedding gown collection.

Asian Lingerie Manufacturer

Comfort-First Intimate Apparel Line

A major Asian intimate apparel manufacturer sought breathable lining mesh that could maintain structural integrity in bras while completely eliminating skin irritation complaints.

Facing similar challenges? Let us analyze your specific needs.

Share Your ChanllengesSolution Overview

Every challenge demands a unique solution. See how we matched our diverse mesh fabric categories to each client's specific requirements, delivering measurable performance improvements.

Client A Solution

Custom-Engineered Power Mesh

We developed a specialized power mesh with 88% stretch recovery rate, engineered for consistent compression performance across 50,000+ production units.

Client B Solution

Custom Bridal Sheer Mesh

We created custom sheer mesh in ivory and blush tones with enhanced softness treatment, ensuring luxurious feel and consistent transparency for delicate bridal applications.

Client C Solution

Anti-Friction Lining Mesh

We supplied OEKO-TEX® certified lining mesh with enhanced moisture-wicking properties and anti-friction surface treatment for ultimate skin comfort.

Need a customized solution for your project? Our experts are ready to help.

Discuss Your RequirementsActivewear Brand Transformation

How a European sportswear label achieved 40% fewer returns and 3x reorder rate with our custom-engineered Power Mesh solution.

Featured Case

Featured Case

European Sportswear Label

Stretch / Power Mesh ApplicationThe client required high-performance mesh with consistent elasticity across large production runs for their competitive athletic wear line. Their existing supplier delivered inconsistent stretch recovery, resulting in garments that lost compression after just a few wears—driving up return rates and damaging brand reputation.

We supplied custom-engineered power mesh featuring 88% stretch recovery rate, specifically calibrated for athletic wear compression zones. Our advanced warp-knitting technology ensured uniform tension across every meter, guaranteeing consistent performance in 50,000+ units.

Ready to achieve similar results? Request Power Mesh samples today.

Explore Power MeshBridal Designer Partnership

How a US bridal collection achieved 98% client satisfaction and established a 5-season partnership with our custom Sheer Mesh.

US Bridal Collection

Sheer / Lightweight Mesh ApplicationThe designer required ultra-fine mesh with consistent transparency and exceptionally soft hand-feel for their premium wedding dress collection. Their previous supplier's mesh had visible variations in sheerness and felt scratchy against delicate skin—unacceptable for luxury bridal wear.

We developed custom sheer mesh in ivory and blush tones with enhanced softness treatment specifically for delicate skin contact. Our precision manufacturing ensures perfect transparency consistency across every roll, meeting the exacting standards of high-end bridal applications.

Premium Quality

Premium Quality

Creating bridal or evening wear? Experience our Sheer Mesh quality.

More Bridal Dress Tulle FabricLingerie Brand Excellence

How an Asian intimate apparel manufacturer eliminated skin irritation complaints and scaled to 200K units annually with our Lining Mesh solution.

OEKO-TEX® Certified

OEKO-TEX® Certified

Asian Intimate Apparel Manufacturer

Lining Mesh ApplicationThe manufacturer sought breathable lining mesh that could maintain structural integrity in bras while completely eliminating customer complaints about skin irritation. Their previous mesh trapped moisture and caused discomfort during extended wear, resulting in returns and negative reviews.

We provided anti-friction lining mesh with enhanced moisture-wicking properties and OEKO-TEX® certification. The specialized surface treatment eliminates skin irritation while the engineered structure maintains bra shape throughout all-day wear, delivering confidence and comfort.

Creating intimate apparel? Discover our skin-friendly Lining Mesh.

Request Lining Mesh SamplesTechnical Support

Behind every successful case study is our comprehensive technical support system. We provide detailed fabric analysis and leverage advanced manufacturing technology to ensure optimal performance for your specific applications.

Fabric Composition Analysis

We provide comprehensive fiber composition reports for each project, analyzing yarn properties, blend ratios, and structural characteristics to match your exact performance requirements.

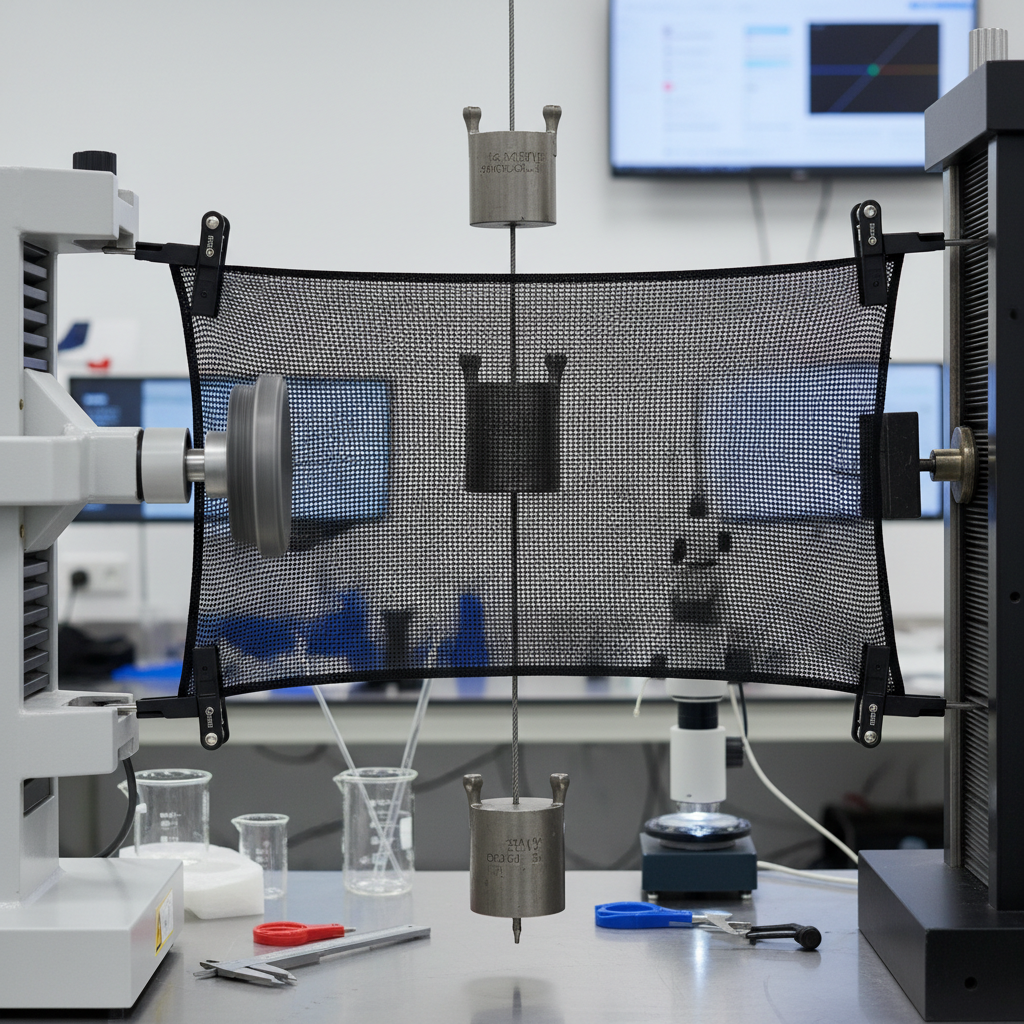

Advanced Warp-Knitting

Our state-of-the-art warp-knitting technology creates stable, uniform mesh structures with consistent hole sizes and superior dimensional stability across production runs.

Performance Testing

Rigorous testing protocols verify stretch recovery, tensile strength, colorfastness, and dimensional stability, ensuring your mesh meets all specified performance criteria.

Dedicated Engineering Team

Our technical specialists work directly with your team to solve complex fabric challenges, providing expert guidance from initial concept through final production.

Need technical guidance for your project? Connect with our engineering team.

Get Technical SupportCustomization Capabilities

Every successful case study features customized solutions tailored to specific client needs. Our flexible manufacturing capabilities transform your unique requirements into production-ready fabrics.

From Client B's request for specific bridal colors and softness treatments to Client A's need for precise compression specifications—we deliver exactly what your designs demand. Our customization services ensure every batch meets your unique standards.

Custom Color Matching

Match any Pantone reference or custom sample with precision dyeing technology that ensures batch-to-batch consistency.

Special Finish Treatments

Add softening, anti-friction, moisture-wicking, or antibacterial treatments to enhance fabric performance.

Custom Specifications

Adjust GSM, mesh density, stretch ratio, and width specifications to meet your exact design requirements.

Have unique customization requirements? Let's create your perfect mesh fabric.

Start Custom ProjectQuality Control & Verification

Every case study success is built on our rigorous quality management system. From raw material inspection to final delivery, we ensure consistent performance that meets international standards and exceeds expectations.

Raw Material Testing

Every yarn batch undergoes tensile strength, color consistency, and purity testing before production.

In-Process Monitoring

Real-time quality checks at each production stage detect deviations immediately for correction.

Sample Approval

Production samples are submitted for client approval, ensuring alignment with specifications before bulk run.

Final Inspection

100% visual inspection and lab testing verify stretch recovery, colorfastness, and dimensional stability.

Need quality documentation for your records? Request certificates and test reports.

Request Quality DocumentsCustomer Feedback

Hear directly from the brands featured in our case studies. Their experiences reflect our commitment to quality, service excellence, and partnership success.

European Activewear

Sportswear Brand, Germany

"The Stretch Mesh transformed our athletic leggings line. The consistent elasticity across 50,000+ units means every customer gets the same premium compression and support. Our return rate dropped 40%—the ROI speaks for itself."

Bridal Collection

Designer, United States

"The Sheer Mesh is exactly what luxury bridal demands—perfect transparency, impossibly soft hand-feel, and flawless consistency roll after roll. Our illusion necklines have never looked better. Five seasons and counting!"

Asian Lingerie

Manufacturer, China

"Switching to their Lining Mesh eliminated our skin irritation complaints completely. The anti-friction surface and moisture-wicking properties keep our customers comfortable all day. We've scaled to 200K units annually with zero quality issues."

Ready to join our success stories? Start your partnership today.

Become a PartnerDelivery & Support

Behind every successful case study is our commitment to on-time delivery and comprehensive support. We ensure your production schedules stay on track with reliable logistics and responsive service.

Global Shipping Options

Multiple shipping methods including sea freight, air cargo, and express courier. Door-to-door delivery available to major markets worldwide.

Dedicated Account Manager

Your assigned account manager provides real-time order tracking and proactive communication throughout production and shipping.

After-Sales Support

Professional technical support for any post-delivery questions. We stand behind our products and help resolve any concerns quickly.

Need reliable delivery for your project? Get a quote with lead time estimate.

Request QuoteCost Effectiveness & ROI

Our case study clients don't just get quality mesh—they achieve measurable business results. See how strategic fabric sourcing delivers real returns on investment.

Using Apparel Mesh products not only elevates garment quality but also helps clients reduce production costs and achieve stronger market competitiveness. Our factory-direct pricing and consistent quality minimize waste and returns.

Reduced Return Rates

Consistent quality means fewer defects and returns. Client A achieved 40% reduction in product returns after switching to our mesh.

Factory-Direct Pricing

As a source manufacturer, we eliminate middlemen and pass savings to you. Competitive pricing without compromising quality.

Higher Reorder Rates

Quality breeds loyalty. Our clients reorder at 3x the industry average rate, demonstrating long-term satisfaction.

Ready to improve your ROI? Let's calculate your potential savings.

Get Cost AnalysisMarket Trends & Future Outlook

Stay ahead of the curve with emerging trends in apparel mesh applications. Understanding market dynamics helps you make informed sourcing decisions and capitalize on growth opportunities.

Athleisure Dominance

The athleisure market continues explosive growth as consumers demand versatile garments for both workout and lifestyle. Power mesh is essential for this hybrid category.

Sustainable Demand

Consumer preference for eco-friendly materials drives rapid adoption of recycled mesh fabrics. Brands increasingly require certified sustainable options.

Technical Innovation

Advanced functional finishes like antimicrobial treatments and enhanced moisture management gain traction for premium positioning.

Comfort-First Intimate

Rising focus on comfort and wellness expands the intimate apparel sector. Breathable mesh linings become standard for health-conscious consumers.

Want to capitalize on these trends? Let's discuss your market strategy.

Get Market InsightsCompetitive Advantages

What sets us apart from competitors? Our unique combination of manufacturing expertise, flexible service, and quality commitment delivers unmatched value for your apparel mesh needs.

Source Factory Direct

As a direct manufacturer with 15+ years of warp-knitting expertise, we control quality at every step and offer competitive factory-direct pricing without middlemen markups.

Flexible MOQ & Supply

We accommodate orders of all sizes—from development samples to bulk production. Our flexible supply chain adapts to your changing needs and timelines.

Full Customization

Your unique requirements become reality. Custom colors, specifications, and finishes ensure your mesh fabric matches your exact design vision and performance needs.

Experience our advantages firsthand. Request samples and see the difference.

Get Free SamplesReady to Transform Your Product Line?

Join the ranks of successful brands who have elevated their garments with our high-performance apparel mesh. From activewear to bridal to intimate apparel—our solutions deliver measurable results. Let's create your success story together.

Trusted By Brands Worldwide

FUZHOU HG TEXTILE

We specialize in high-performance apparel mesh fabrics for activewear, intimate apparel, bridal, and fashion applications. With 15+ years of warp-knitting expertise and factory-direct pricing, we help designers and manufacturers source the perfect mesh solutions for their exact needs.

Direct Contact

Start Your Success Story

Tell us about your project requirements. Our team will respond within 24 hours with tailored solutions and samples.